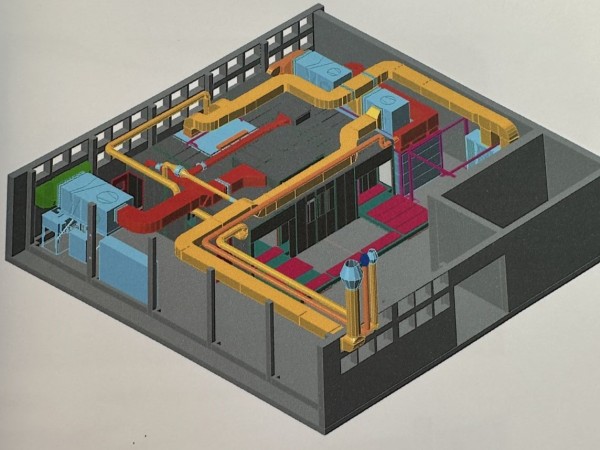

KRAUTZBERGER SKID 30-U9, automatic painting system with ventilation system

Krautzberger GmbH SKID 30-U9

Plant components:

The whole surface treatment plant consists of the following main components:

- Water-flooded spray booth with automatic paint sludge discharge unit

- Booth enclosure as closed booth with integrated supply air filter ceiling

- Exhaust booth with supply air filter ceiling and exhaust air system

- Supply air system

- Drying booth with recirculation/exhaust air system

- Driven conveyor as skid system including workpiece holders

- 3-axis spraying unit with automatic spray guns

- Paint supply system

- Equipment for daily paint storage/color preparation room

- Paint spraying wall as manual work station

- Switching and control system

Scope of delivery:

Steel cabin construction

- side wall cladding

- cabin ceiling

- supporting structure

- pneumatically controlled sliding gates at dryer inlet and outlet

air circulation unit

- profile frame construction

- fan part

- heater part with retractable heat exchanger Cu/Al, steel header for hot water

- Mixing and filtering section, pocket filter with removable filter pockets of EU4 grade

- canvas spigot

Duct system

- frontal blowing-in via vertical filter wall

- frontal suction (opposite to blowing) through vertical filter wall

- connecting ducts

Exhaust air system

- duct system NW250

- Regulating damper NW250

- Deflector hood NW250

Paint spraying plant:

Manufacturer: SPMA Spezialmaschinen GmbH

Model: SKID30U9

Serial number: 80808/0103

year of construction: 2002/2003

Voltage: 400V AC

Frequency: 50Hz

Power: 12kW

Pass-through drying cabin:

The dryer capacity is designed for 11skids.

Usable room dimension: 2,1x6,5x1,94m (WxLxH)

Outside dimension: 2,22x7,22x3,2m including recirculation unit (WxLxH)

recirculation air volume: 6.000m3/h

Exhaust air volume: 500m3/h

Supply air volume (from hall): 500m3/h

Injection temperature: approx. 65°C, infinitely variable

Heating medium: hot water 90/70°C

Heating capacity: approx. 40kW

Filter: EU4 pocket filter

drive motor: 2,2kW

Supply air unit:

Air volume: 9.000m3/h

P-external: 250Pa

Intake temperature: -12°C

Inlet temperature: +22°C

Heat output: 103kW

Heating medium: hot water VL 70°C/RL 55°C

Motor power: 2,2kW

Extraction evaporation area:

Exhausted air volume: 1.500m3/h

Fan: 0,37kW, Ex-version

Supply air unit:

Type: AT 4 16x12 (indoor installation)

General Downloads

You would like to arrange an inspection on site or by video call? Then get in touch with the on-site contact below and arrange an appointment for the inspection of the lots in the specified period.

Viewing period: by appointment

Location: You will find this directly in the article.

On-site contact: Maik Wehner, Phone: +49 (0) 351 217 899 46, Email: sales@lagerwerk.com

As a method of payment we offer prepayment by bank transfer. You will find all necessary information in your order confirmation or proforma invoice.

As soon as we have received the full invoice amount, we will send you your invoice by email.

The conditions for the collection of the auctioned lots are:

- the complete receipt of payment at Lagerwerk

- the arrangement of an individual collection date (to make an appointment, please contact the below mentioned on-site contact)

If you would like to commission a third party with the collection, we will be happy to recommend a reliable service provider and will be happy to assist you in providing the required information.

NOTE: If required, we can also take over disassembly and packaging as well as shipping as a service for you. Simply contact us for this purpose.

Collection period: by appointment

Location: You will find this directly in the article.

On-site contact: Maik Wehner, Phone: +49 (0) 351 217 899 46, Email: sales@lagerwerk.com

The machines and equipment must be professionally disassembled and removed independently. EXW (see Incoterms)

Auxiliary means for disassembly and loading from the respective location are not available.

NOTE: If required, we can also take over disassembly and packaging as well as shipping as a service for you. Simply contact us for this purpose.

Do you have any questions about the item, viewing, payment, collection, disassembly or other questions about the auction? Just get in touch with us:

On-site contact: Maik Wehner

Phone: +49 (0) 351 217 899 46, Email: sales@lagerwerk.com LinkedIn